Syndromes/Craniofacial Anomalies

188 - Viability of a Digital Workflow for NAM Appliances

Gustavo A. Garza, DDS

Dental Resident

University of Texas Health Science Center-Houston

UT Health - Houston

Houston, Texas, United States- BA

Bhavini Acharya, BDS

Pediatric Dentistry Graduate Program Director

University of Texas Health Science Center-Houston

Houston, Texas, United States - FK

Fred Kasper, PhD

University of Texas Health Science Center - Houston

- MT

Michelle Thompson, DDS

University of Texas Health Science Center - Houston

Brett T. Chiquet, DDS, PhD (he/him/his)

Professor and Chair, Department of Pediatric and Community Dentistry

University at Buffalo School of Dental Medicine

University at Buffalo School of Dental Medicine

Buffalo, New York, United States

Brett T. Chiquet, DDS, PhD (he/him/his)

Professor and Chair, Department of Pediatric and Community Dentistry

University at Buffalo School of Dental Medicine

University at Buffalo School of Dental Medicine

Buffalo, New York, United States- BA

Bhavini Acharya, BDS

Pediatric Dentistry Graduate Program Director

University of Texas Health Science Center-Houston

Houston, Texas, United States

Presenting Author(s)

Co-Author(s)

Research Mentor(s)

Program Director(s)

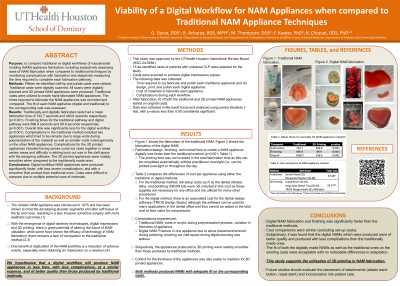

Purpose: The purpose of this study is to compare traditional vs digital workflows of nasoalveolar molding (NAM) appliance fabrication, including subjectively assessing ease of NAM fabrication when compared to traditional techniques by monitoring complications with fabrication and objectively measuring the time required to complete each fabrication pathway.

Methods: Fifteen de-identified cleft lip and palate (CLP) digital scans and traditional casts will be utilized. Traditional casts were digitally scanned. All scans were digitally planned and 3D printed NAM appliances were produced. Traditional casts were utilized to create hand-fabricated NAM appliances. The time required to fabricate 3D printed and traditional NAM appliances was recorded and compared. The fit of each NAM appliance (digital and traditional) to the corresponding cast was assessed. Data analysis pending.

Results: Traditionally and digitally fabricated casts had a mean fabrication time of 742.7 seconds and 446.6 seconds respectively (p < 0.001). Finishing times for the traditional pathway and digital pathway were 696.9 seconds and 89.9 seconds respectively (p < 0.001). Overall time was significantly less for the digital workflow (p < 0.001). Complications in the traditional method included two appliances which had to be remade due to large voids during polymerization of the material as well as smaller voids noted generally on the other NAM appliances. Complications for the 3D printed appliances included having sprues come too close together in areas certain areas and difficulty in adding bock out wax in the cleft space with the designing software. The 3D printed appliances were notably smoother when compared to the traditionally made ones.

Conclusions: Digital workflow NAM appliances were produced significantly faster, with less severe complications, and with a smoother final product than traditional ones. Costs were difficult to compare due to multiple potential uses of materials.

Identify Supporting Agency and Grant Number:

.jpg)